Your basket is currently empty!

Savolit Plus

wood wool boards

natural building boards

for sustainable construction

Savolit Plus is the result of continuous research and the desire to provide the best environmentally friendly products and solutions. Savolit Plus wood wool boards are genuine natural panels and consist of long, strong wood fibres which are mineralised and bonded into panels. The raw timber originates from sustainably managed forests and is PEFC labelled. From production, installation, lifespan and decomposition (recycling) Savolit Plus panels do not pose a risk to the environment. Savolit Plus wood wool boards are 100% recyclable.

Why choose Savolit Plus

- Higher resistance to moisture and frost

- Higher flexural strength

- Higher compressive strength

- Low environmental impact

- PEFC certified timber from sustainably managed forests

- Wide range of panel sizes and thickness

Savolit Plus Applications

- External cladding of timber frame walls

- Internal lining of timber frame walls

- Base Board for plastered ceilings and walls

- Internal partition walls

- Carrier board for render

Composition

Savolit Plus wood wool boards consist of long strong wood fibres, stabilised by chemical impregnation and bound by cement-binding agent into a compact coherent structure. The mineralisation process strongly increases the fire resistance of wood wool. The composition and performance of the boards make them ideal for many different applications in building constructions.

As a result of Plus panels composition, tests have shown that they are unaffected by moisture and frost.

Produced in accordance to standard EN 13168 and are CE and UKCA marked.

Savolit Plus timber comes from forests certified PEFC that are sustainably managed.

Boards are PEFC certified and are also available with FSC® certification.

Please contact us for details regarding our FSC® certified products.

View the Savolit certificate of constancy of performance (PDF).

Ecological & health aspects

- Many sustainable benefits

- Boards are made of natural materials

- No waste disposal problem

- Ideal for buildings comfortable for people sensitive to allergies

- Recommended for healthy living environments

- No harmful gases or vapours given off

- No toxic fumes if burned

- Diffusion permeable

- Hygroscopic – levels out humidity level changes

- Naturally resistant to fungus and insects

Technical advantages

- Unaffected by humidity and frost

- Durable

- Non flammable and self extinguishing

- Thermally insulating

- Compatible with all normal construction materials

- High compression resistance and flexural strength

- Stable

- Surface offers good mechanical key for renders and plasters

- Sound absorbing and noise insulating

- Vapour permeable

- Easy and safe to handle, cut and work

- Proven performance in over 80 years in all climates

- Available in wide range of board sizes

- Low environmental impact

- PEFC certified

Technical Data

| Property | Designation | Units | Data | Standard | ||||

|---|---|---|---|---|---|---|---|---|

| Board thickness | d | (mm) | 15 | 25 | 35 | 50 | 75 | |

| Board length | l | (mm) | 2400 2000 1200 |

2400 2000 1200 |

2400 2000 |

2400 2000 |

2000 | |

| Board width | b | (mm) | 600 | 600 | 600 | 600 | 600 | |

| Average Specific Mass | (Kg/m²) | 8 | 11.5 | 14 | 18 | 26 | EN 1602 | |

| Declared thermal resistance | RD | (m²K/W) | 0.20 | 0.35 | 0.50 | 0.75 | 1.15 | EN 12667 |

| Declared thermal conductivity | λD | (W/mK) | 0.065 | EN 12667 | ||||

| Bending strength | σb | (kPa) | 1700 | 1300 | 1000 | 700 | 600 | EN 12089, A |

| Compressive strength at 10% deformation | σ10 | (kPa) | ≥ 200 | ≥ 200 | ≥ 200 | ≥ 150 | ≥ 150 | EN 826 |

| Water vapour diffusion resistance factor | μ | (-) | 5 | EN 12086 | ||||

| Fire reaction | Euroclass B – s1, d0 | EN 13501-1 | ||||||

| Thickness tolerance | (mm) | +3, -2 | EN 823 | |||||

| Width tolerance | (mm) | ± 3 | EN 822 | |||||

| Length tolerance | (mm) | +3, -5 | EN 822 | |||||

| Squareness | (mm/m) | ≥ 2 | EN 824 | |||||

| Specific heat | kJ/kgK | 1.81 | ||||||

| Capacity for thermal accumulation | kJ/m³K | 965-628 | ||||||

| Capacity for absorption of room humidity | l/m² | 2 – 3.5 | ||||||

| Resistance to water and frost | No alteration and maintenance of bending resistance after 20 cycles of frosting and defrosting in water | |||||||

Dimension tolerances: Slight differences from format cannot be excluded due to the organic nature of wood.

Tolerances according to EN 13168.

Store panels in a dry, level place, not directly on the ground and protect from moisture and dust. The packing provided does not provide protection from rain!

Do not stack more than two pallets on top of each other.

Design

Installation

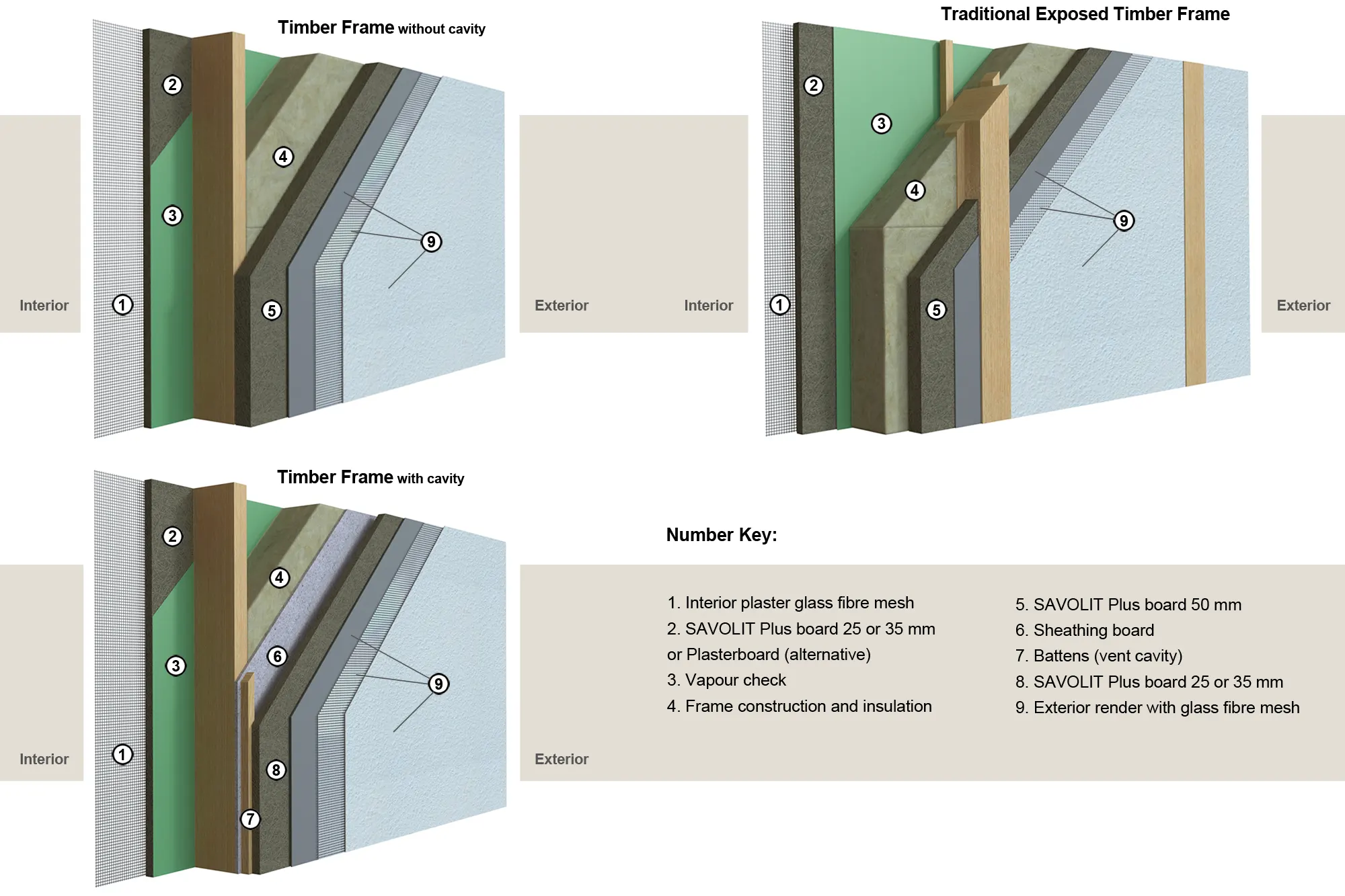

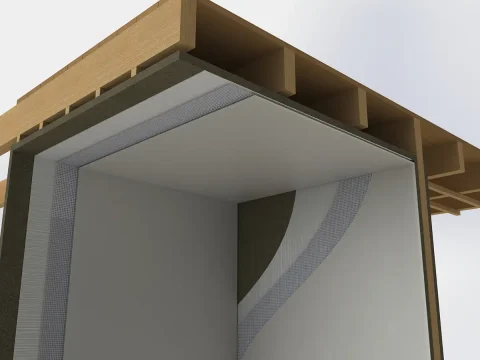

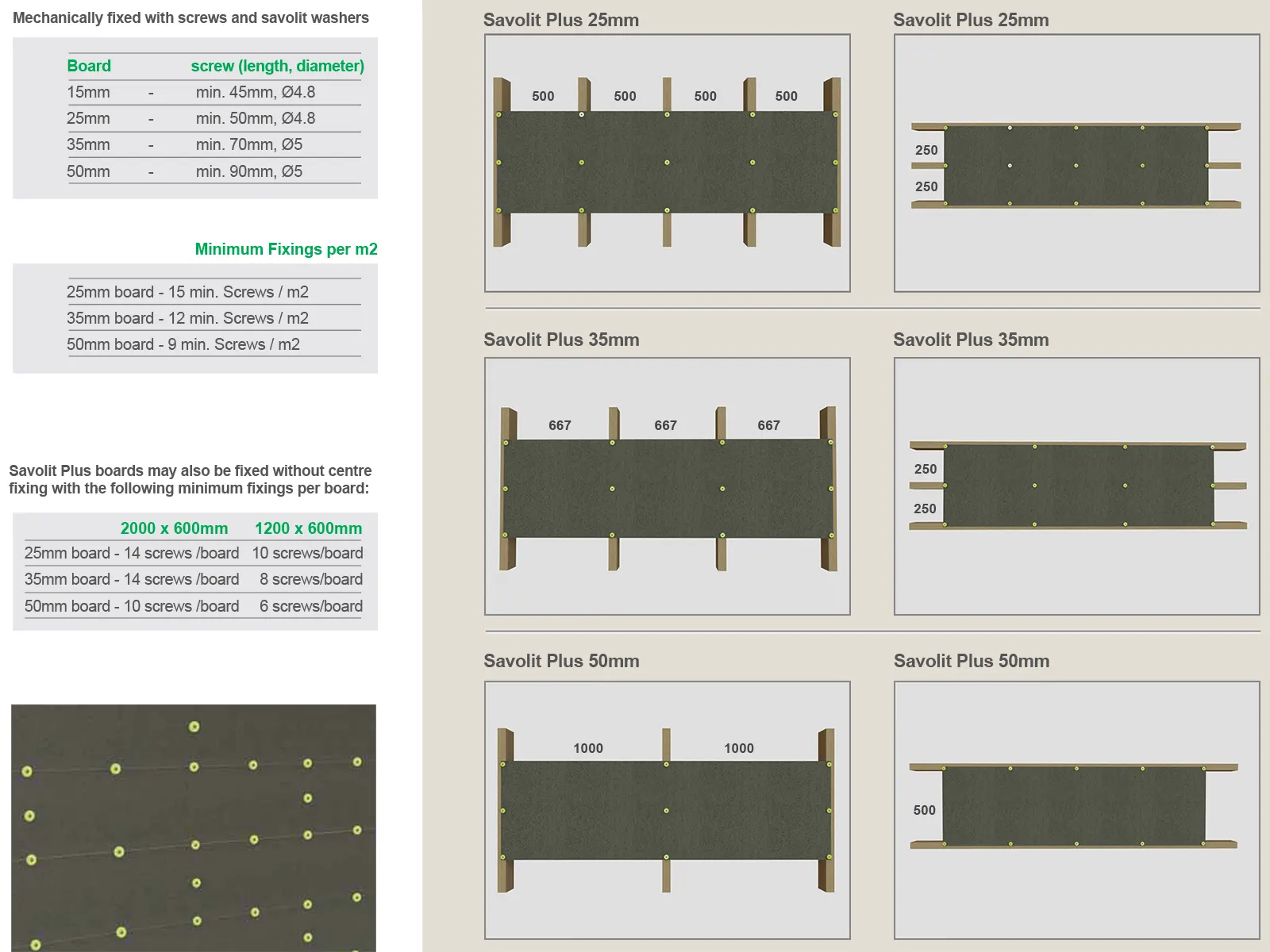

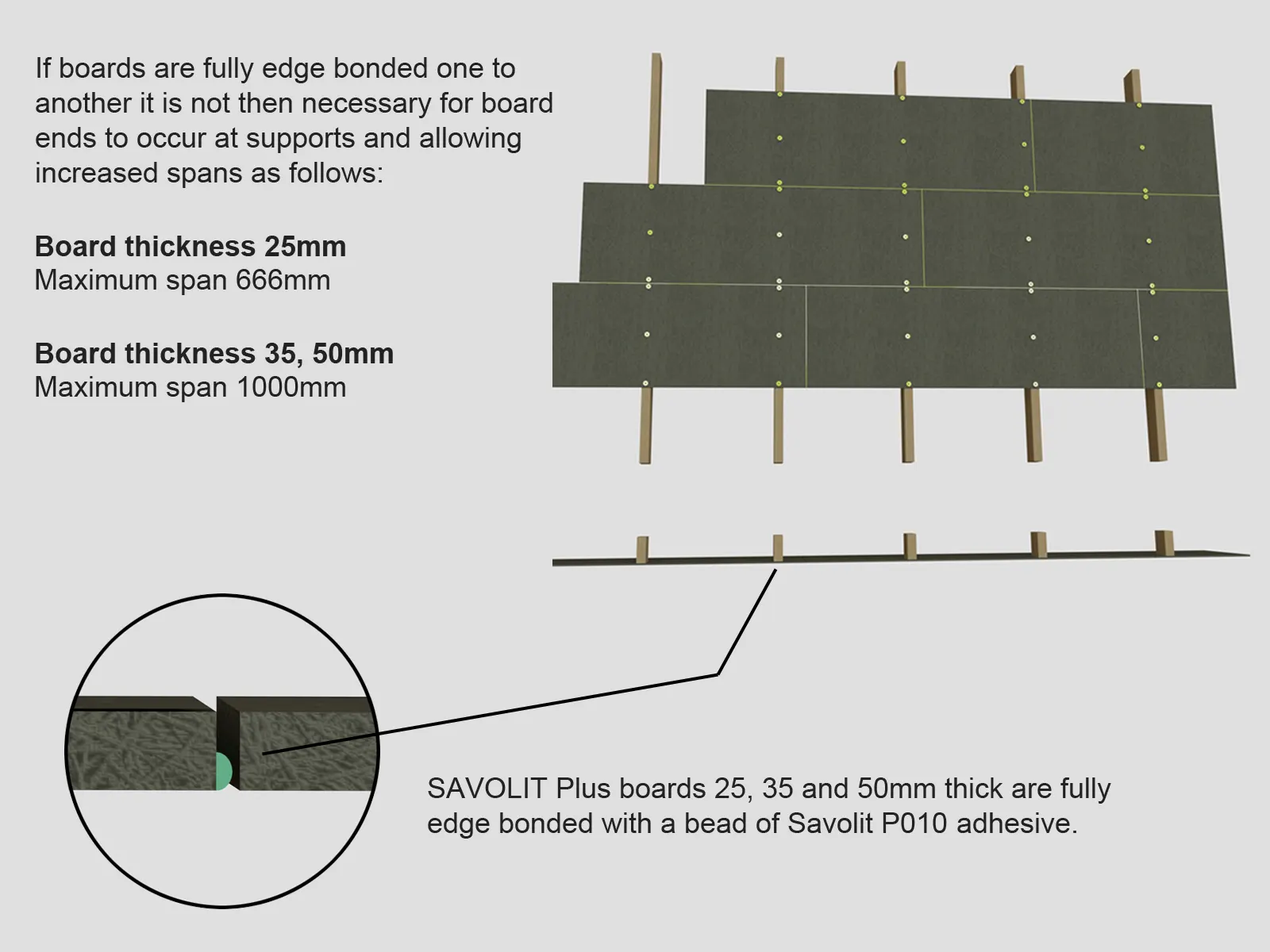

SAVOLIT Plus wood wool boards are installed in a broken bond pattern and fastened to timber structures with timber screws and Savolit washers positioned as shown in the following diagrams.